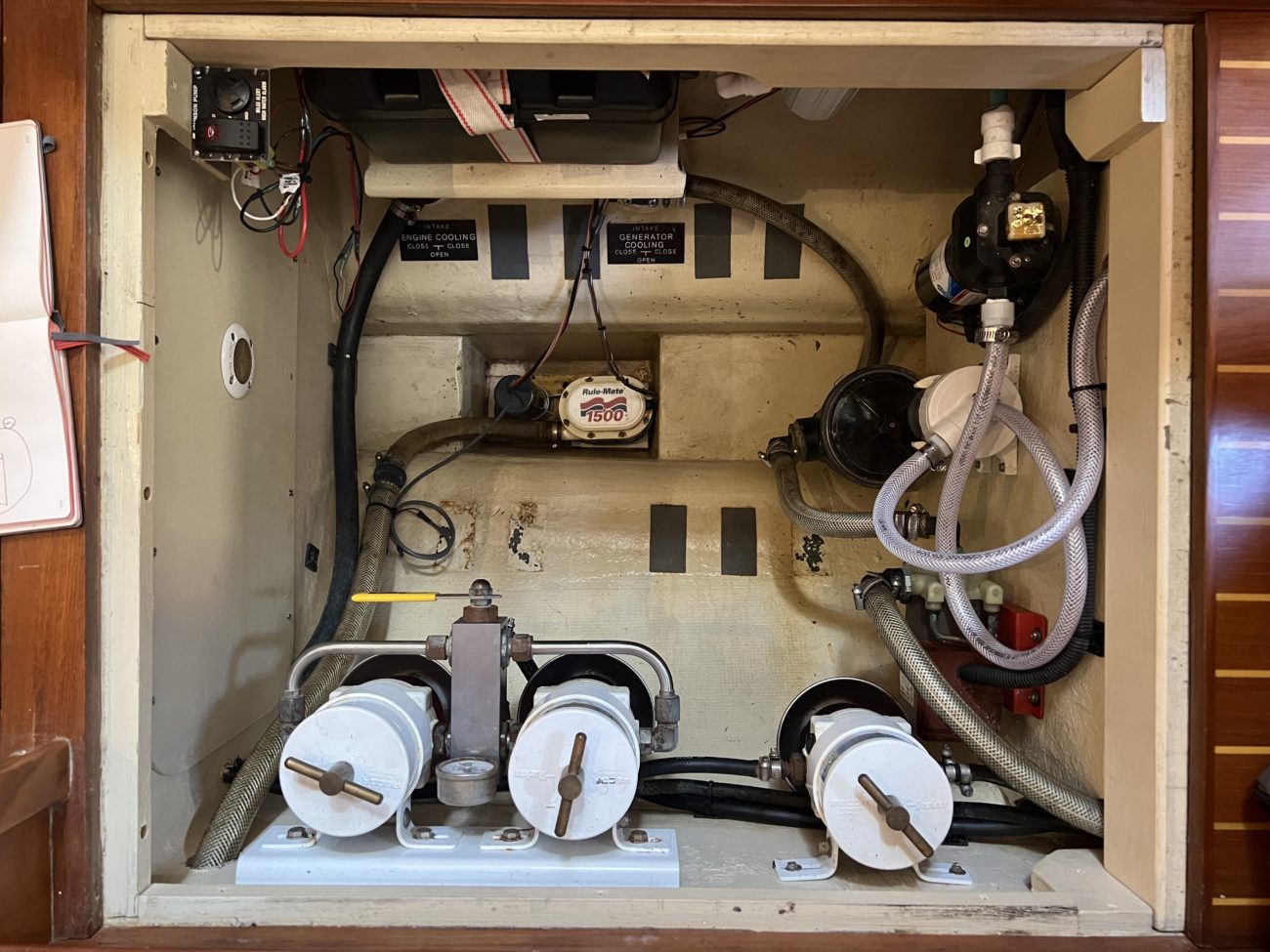

For some reason the bilges on this boat have always been full of water. I’ve been chasing little leaks in the plumbing system the entire time we’ve owned her. I think I’ve finally gotten all of that fixed, but another thing that’s not working right are the bilge pumps. Obviously that’s a super important system that needs to work! Earlier in the season the float switch literally floated on top of the water in the bilge because it came unglued from the bottom of the boat. We cobbles together a little bracket from a piece of aluminum to get us through the Bahamas. Now recently the other side of the boat has been slowly filling with water and the bilge pump only turning on when forced to. There’s something wrong with both sides of the boat and I don’t want to risk sinking so I decided to replace both float switches with nicer, and better designed, new ones and also add a high water alarm just in case.

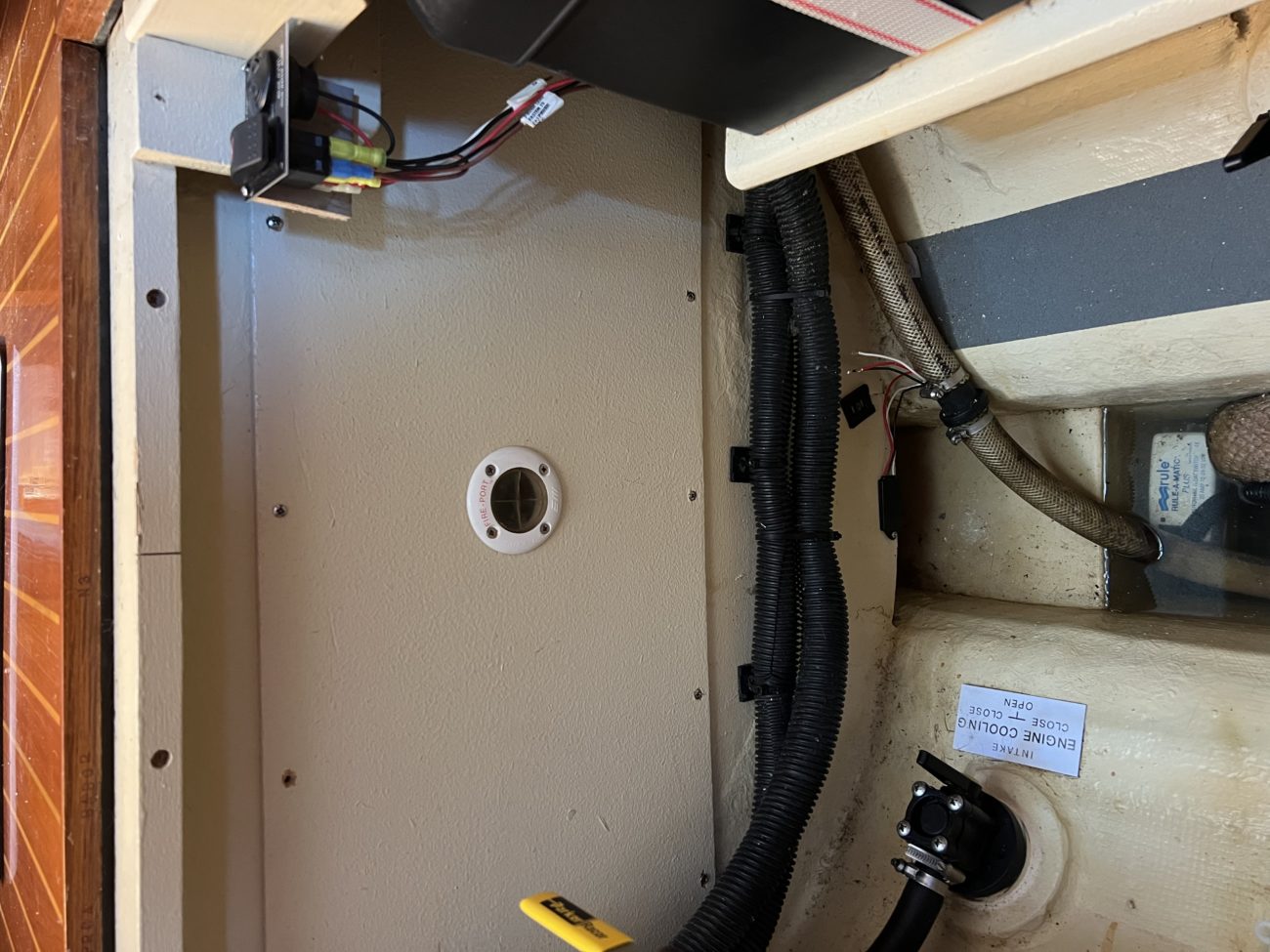

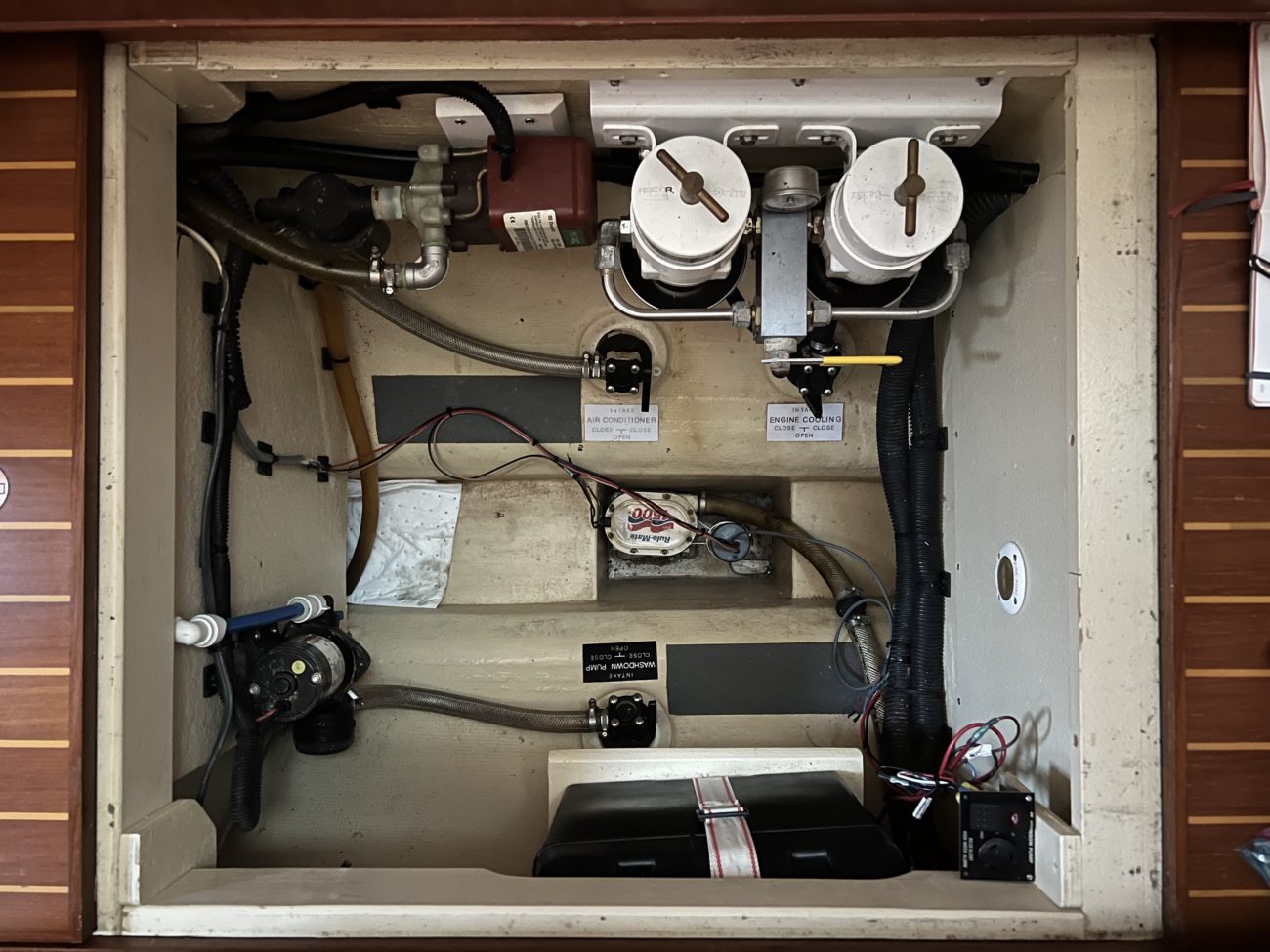

The high water alarm wasn’t too hard to install. I placed the sensor (that emits an ear splitting shriek when it contacts water) on the bulkhead as low as it would go. It shouldn’t ever get water sloshed on it but it’s low enough that we will have time to take action if it ever has reason to activate! It’s wired directly to the engine start batteries and has a nice little control switch. The switch panel was the hardest part since it’s meant to have a hole cut in a bulkhead and flush mount. That’s not something I could do here, so I mounted it facing up underneath the floor panels. I figure if it ever does go off I’m going to be ripping up that floor panel anyway so I might as well just leave the whole system in the bilge!

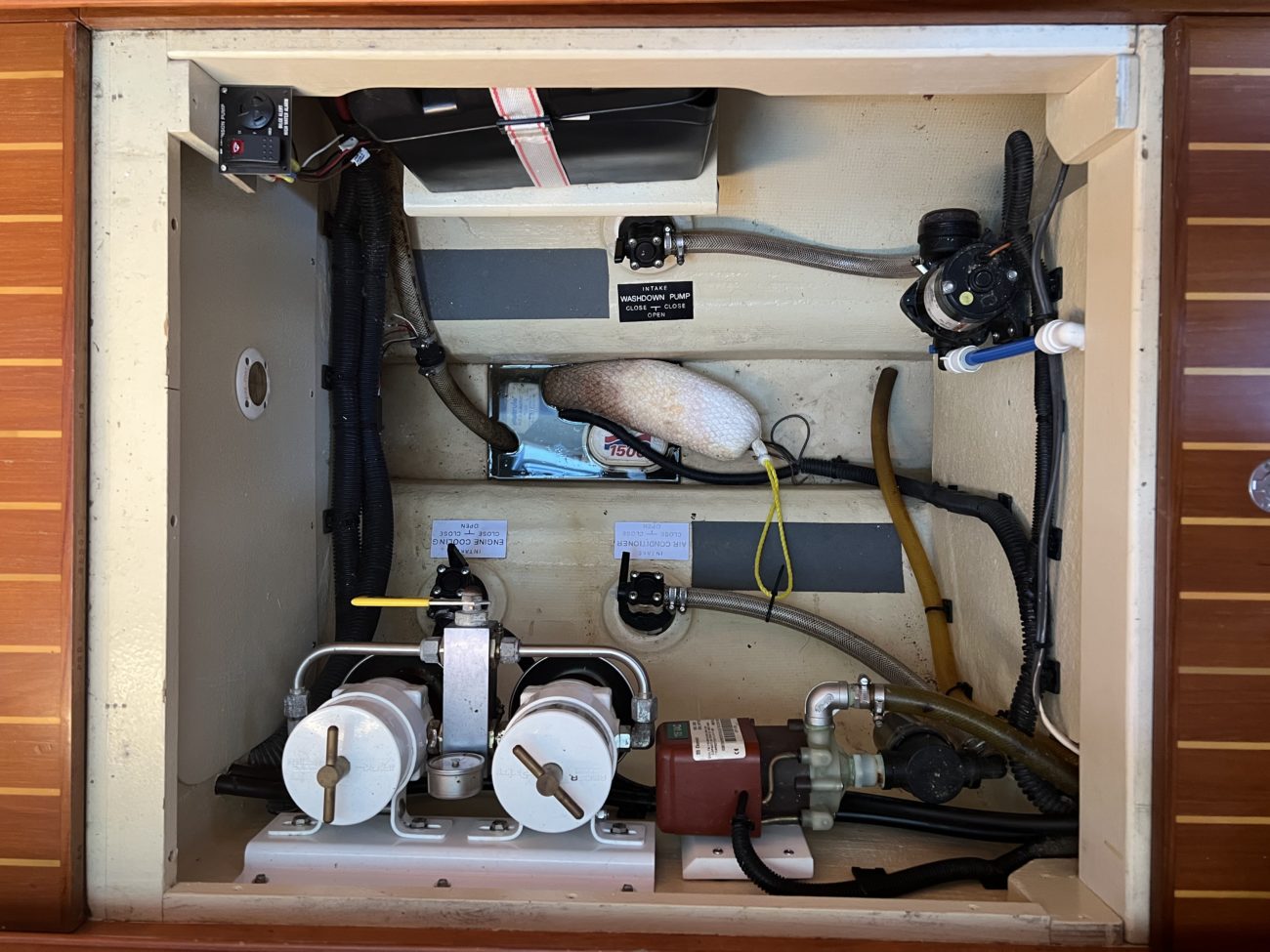

Now it’s time for the float switches. The new ones are wired differently than the old ones so I had to compare wiring diagrams to see what wire did what and where to cut them to remove. After I got the switches removed from both sides I had to take a sponge and a large mixing bowl (mixing bowl is used as a shop tool as often as it’s used for mixing at this point!) and slowly removed the disgusting greasy bilge water.

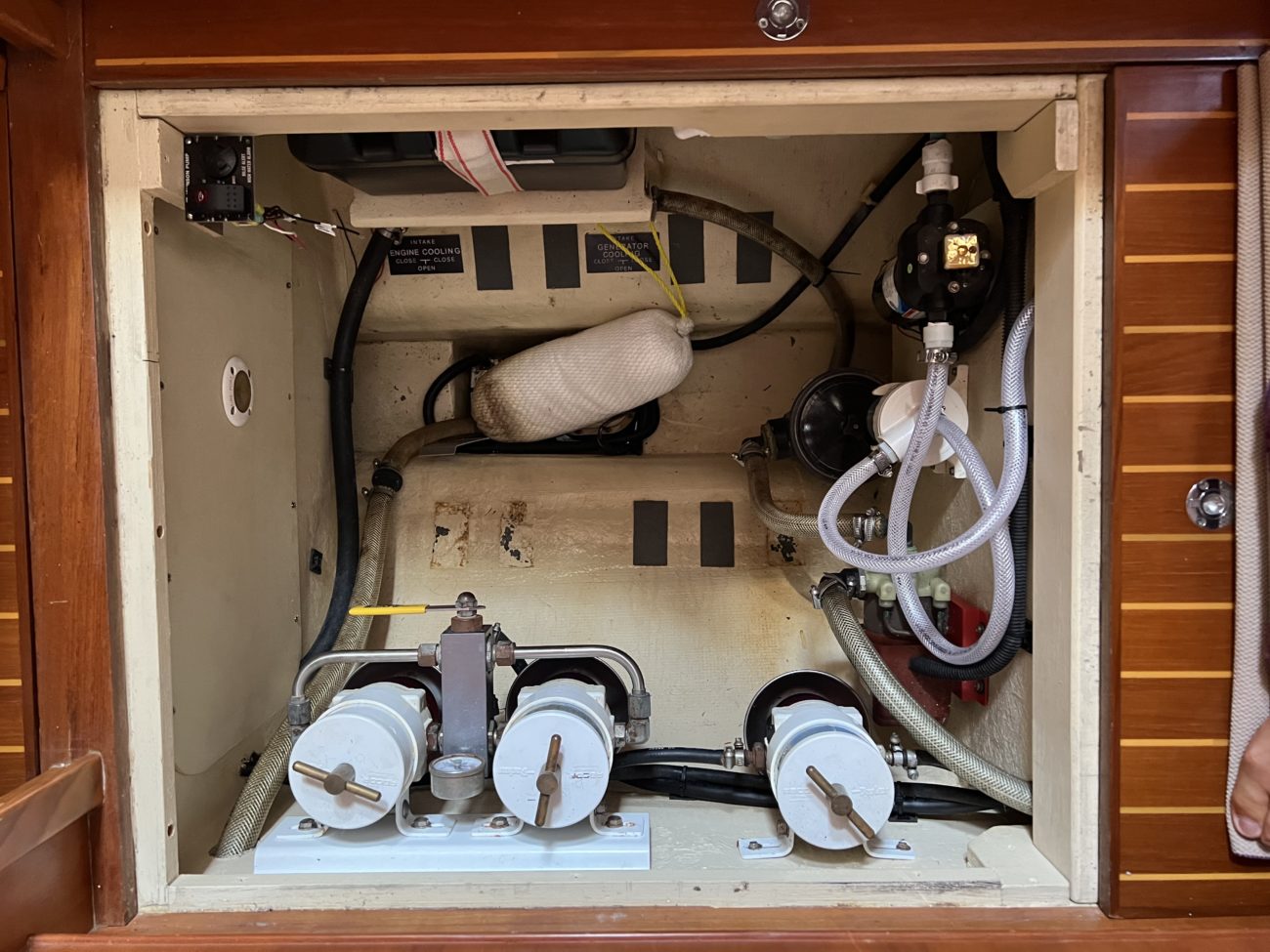

The new switches have a float inside a cylinder and are way more resistant to grease, dirt, and clogging. The installation is pretty easy also: they just clamp around the bilge pump. I used some thick 150# zip ties. The wiring was set up to be pretty easy, however once I started digging into the wiring on the boat I realized we had other issues. One reason the starboard pump wasn’t working consistently was that the wiring was completely rotten and the ground disintegrated in my hand. Awesome.

Someone also used non sealed wire connectors in the bilge, which is against ABYC regulations for hopefully obvious reasons.

Come to find out the reason the port side pump would only turn on when in manual mode was that it was wired backwards so the automatic function didn’t work at all. I finally got all the wiring cleaned up and hooked up correctly.

Now the bilge pumps and switches all work like they should!