As usual, boat life is filled with boat projects both big and small. We have a lot of big plans for the fall for Onward but for now we’re just hammering out the little things so we don’t have to squeeze them in later.

First up: adding a mirror in the bathroom that wasn’t installed by someone 7 feet tall…

Next was our sewage system. There was something definitely wrong with how it was functioning since when you pumped out the tank it would pull water from the toilet as well… While poking around the boat earlier I noticed that the holding tank vent was made from non-sewage-safe water hose (awesome…) that does a neat little circle before it exits the boat. All of these things combined with the tendency for the vents to get clogged sent me to the parts store for replacements. I got an entirely new vent fitting for the hull and since we’re not in a place to upgrade hoses right now, I just cut the existing vent hose to fit up to it. But be prepared… an entire sewage upgrade is in the works since that’s one system that I don’t want to have to deal with when we’re underway!

I’ve already done some work to the kitchen plumbing system with a new faucet and redoing the seawater rinse system, however I also wanted to install a UV purification system like we had on our other boats. I had the rerouted plumbing ready to go with just a tee to cut in to supply the UV system and the actual routing went pretty fast!

Our friend Rob met us at the marina in Merritt, NC to help us re-charge the refrigerant in our refrigerator compressor because it was so low it wouldn’t keep food cold. This did fix the problem and the unit is working like it was designed to however, the evaporator plate is way too small for this size of fridge. One end is frozen solid and the other end got up to 50 degrees so there was really no place to safely keep food cold. We decided that, unfortunately, it’s going to have to be ripped out and redone with a larger plate and new system because I don’t want to risk food going bad in the Bahamas!

We did have another mishap on the boat. When we installed the arch on the transom we knew that the structure there was kind of weak and had planned on reinforcing it substantially when we got to Florida. Unfortunately, Jason slipped while tying up the dinghy, pulled on it hard, and cracked the transom/hull joint. Whoops. We keep epoxy and filler on board so we mixed some up with some structural filler, filled the crack, and then clamped it until it set up. Hopefully that will hold until we get back and can do more.

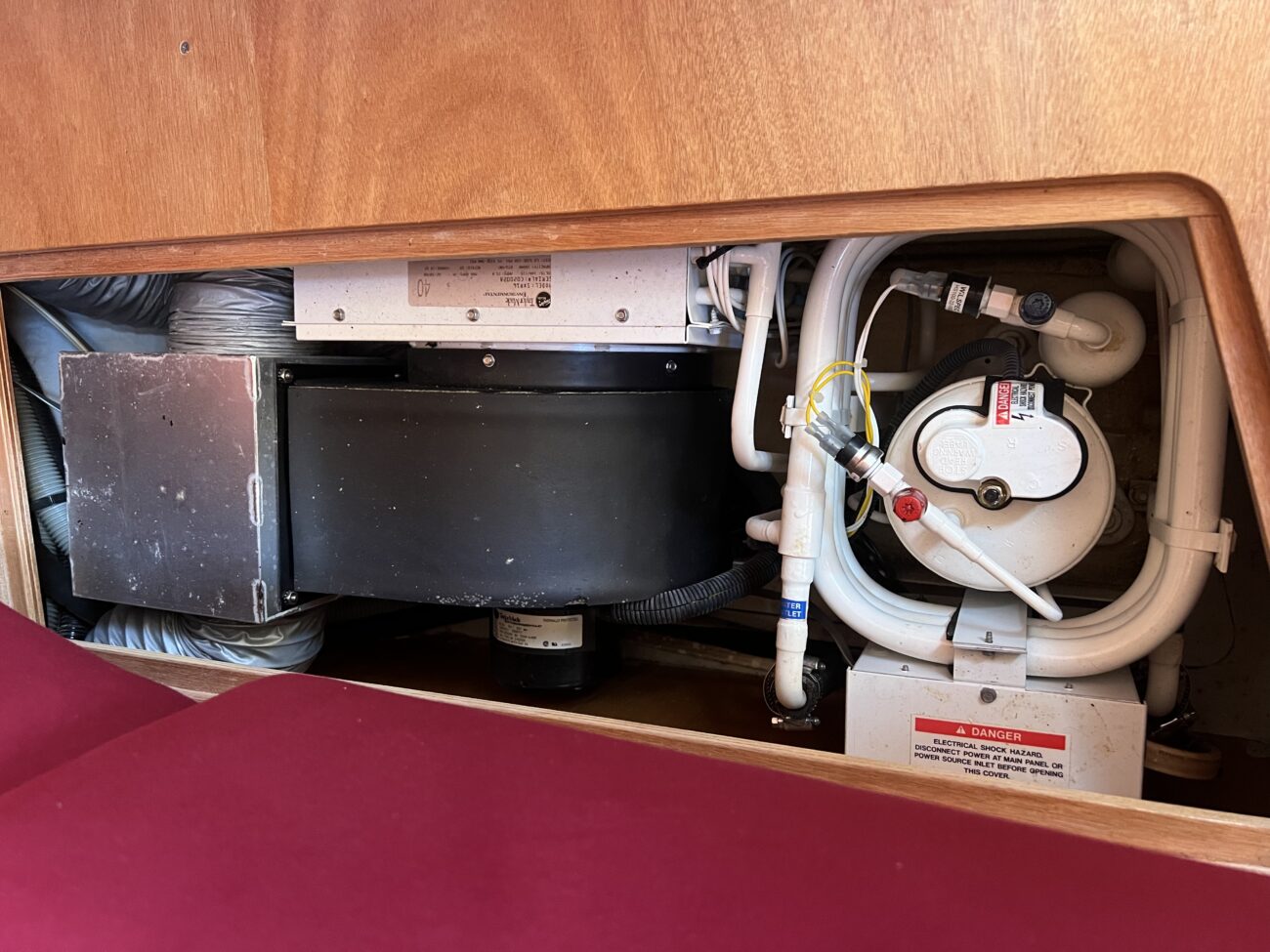

The boat currently has a nice and fully functional air conditioner/heater installed. We would rather have the storage space back, so we ripped it out.

We’ve also just generally been cleaning and organizing the boat and finding things we want to fix next time around.

The wires at the mast are located in an awful spot where the genoa sheet lines rub on them. So they’re pretty destroyed and on our list of things to replace, especially because we’re dropping the mast when we pull the boat out of the water. Each cable has its own little gland that it enters the boat through. While poking around I found that none of the glands were sealed and because of that, the wood used for coring in the boat was wet. I took a pick and painstakingly removed as much of the damaged material as I could. Just waiting for later to be able to fix this properly.