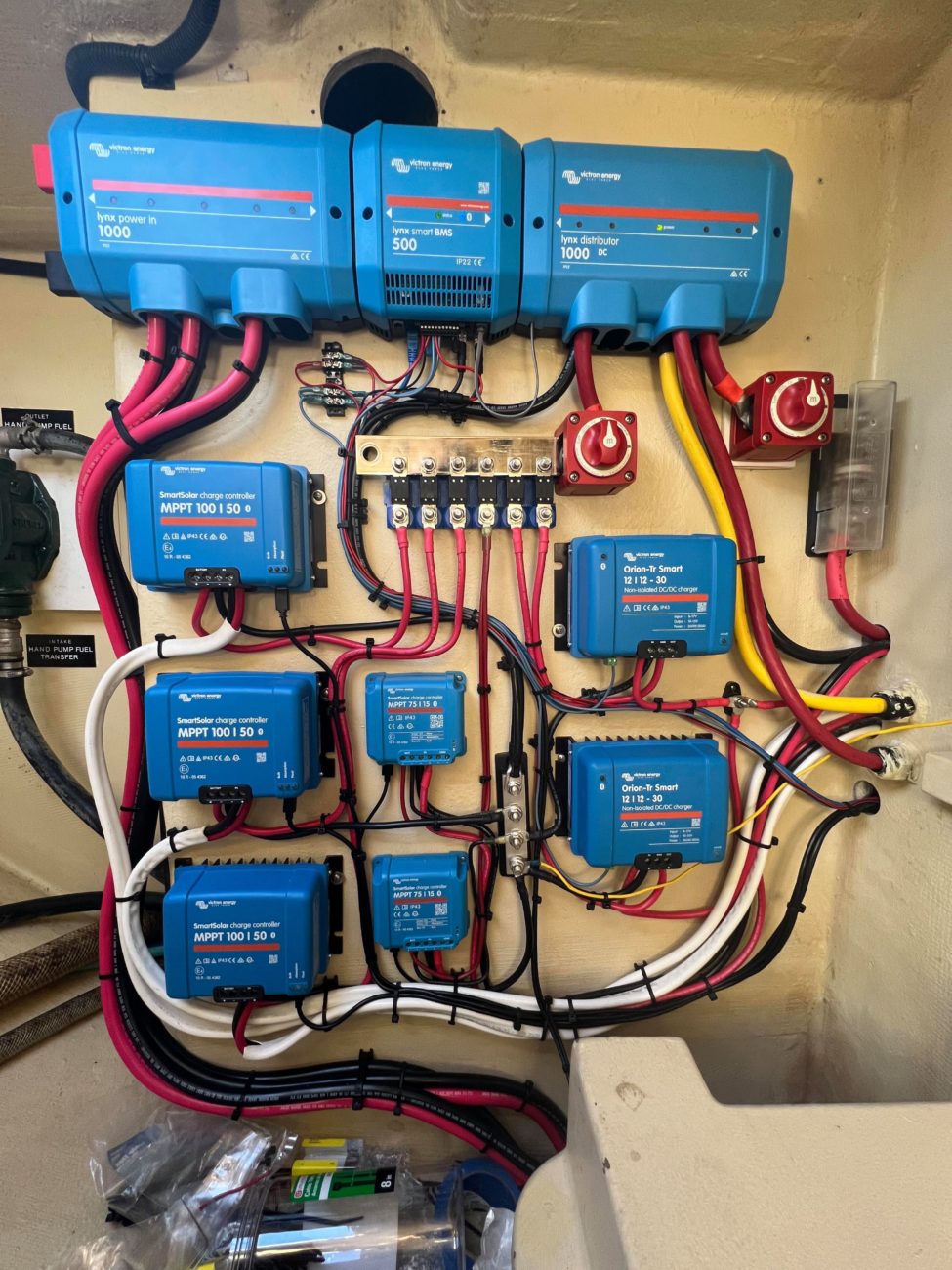

Between the massive solar power upgrade and a few other projects that require electricity, we have a LOT of electrical work to do on True North! Unlike Peregrine where we just ripped everything out and started from scratch, True North is pretty much ready to go so we have to integrate what we do into what’s already there. We’re going to go with the same 600 amp hour lithium battery bank that we had previously, but with a much fancier system. We’ve already run 5 new cables of 6 ga duplex to power the solar panels that will go to 5 individual controllers. We also installed 2 new 6 ga duplex cables to power the dual water maker installation. Aside from the new installations, there are a few other existing cables that needed to be re-routed and/or upsized to be able to carry the load. I’m glad Jason got to sit down and math it all up to figure out how to do it!

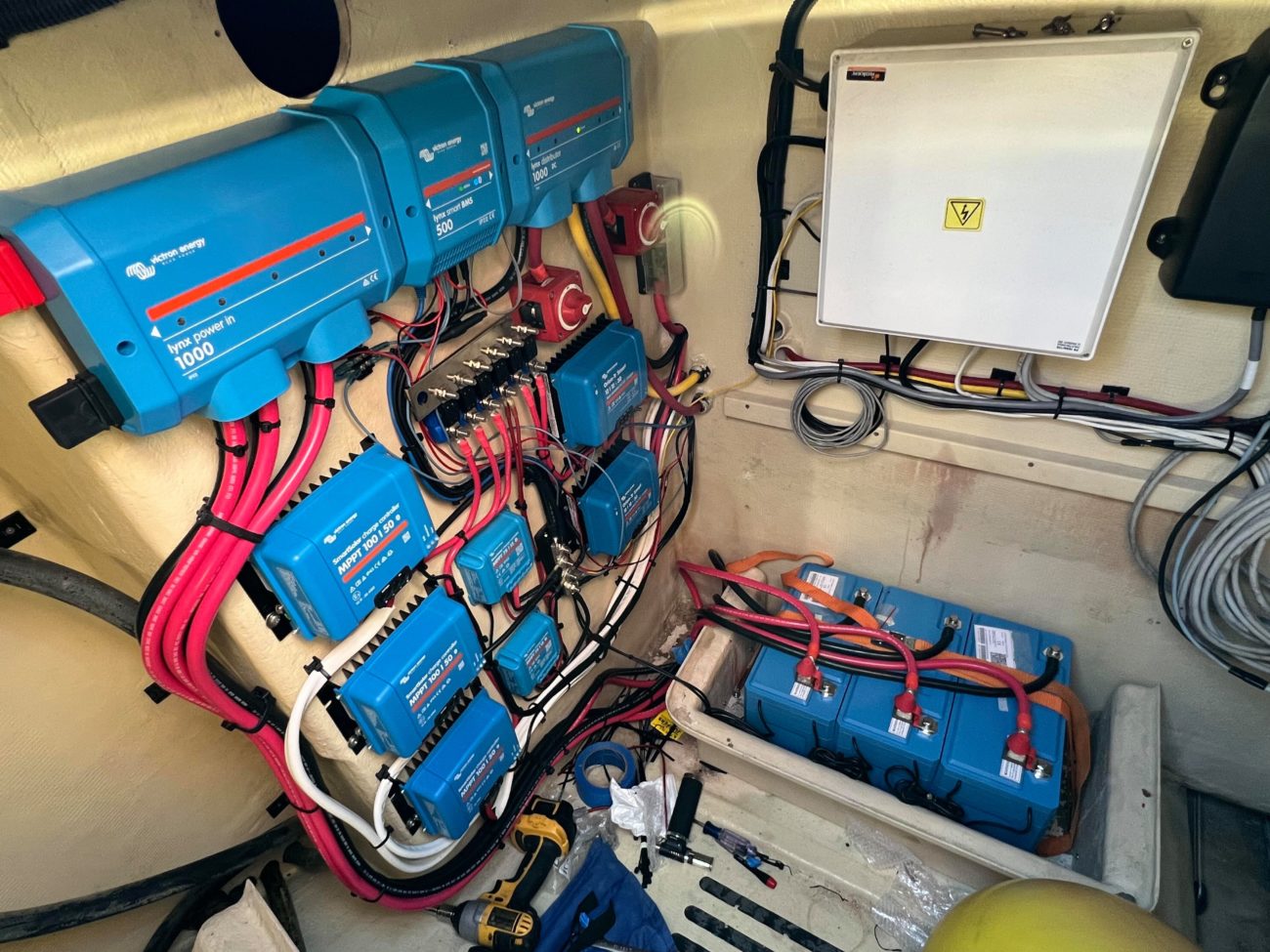

After getting all the equipment mounted (control system, solar controllers, and dc/dc chargers) we just need to run some wires. That will take…way longer than it should! The main point of all of this work is to upgrade the batteries. The boat came with 4 6-volt golf cart batteries. They’re huge, heavy, leak acid, and require water to be filled. The 3 lithium batteries are going to be half the weight, much smaller and almost twice the amount of usable power!

Now it would have been super convenient if we could have just slid 4 new batteries into the same spots, but obviously they’re going to be a little differently sized. We can only fit 3 new batteries into the box and they’re half the height. Jason’s solution was to just chop off the bottom half of the box. I married a genius.

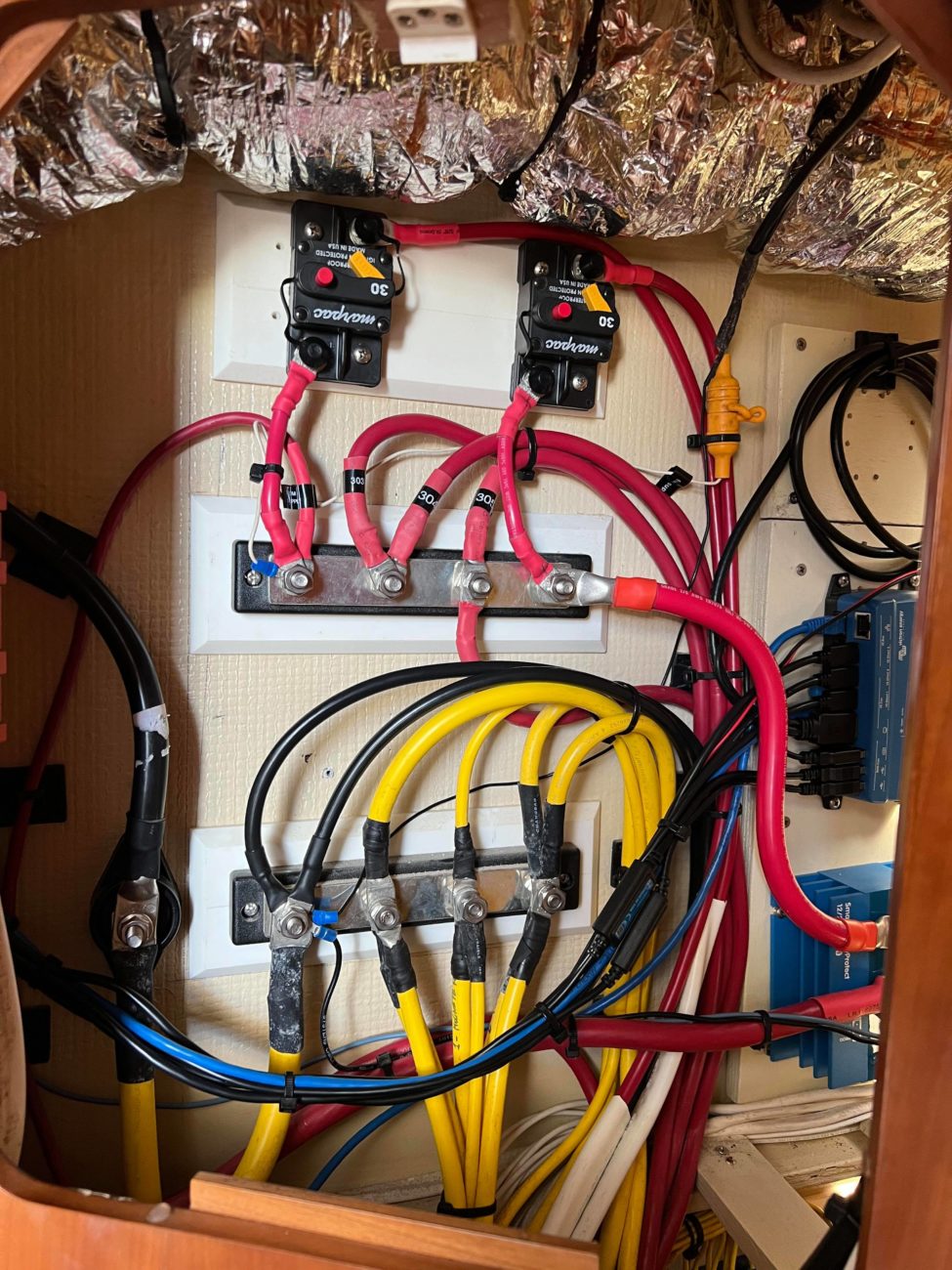

While Jason was up in the battery box dealing with all of the new stuff, I was behind the main electrical panel moving things around. I didn’t get any before shots (dangit).

I installed the breakers for the water makers and routed a bunch of wires. Also took the time to lovingly zip tie them into OCD-approved submission.

While Jason was finishing up some work elsewhere, I took a few minutes to install our fancy new touch screen battery system monitor!

Unless we screwed something up, we’re done with the wiring inside the boat! Jason has been working outside getting the rest of the system wired up. We now have batteries and dad even installed the battery box!

Today I cut a little more clearance in the side of the battery box lid to support all the new battery cables going in and then dad bolted the lid on and relocated the wood bar that the lid locks into. The battery box is now complete!

And a fun side note… my hair is getting long and blocking the output from my headlamp… this is going to have to be fixed!

One thing that worked a little differently on this boat than the last was the charging system for the engine start batteries. They’re not lithium so we had to add small trickle chargers to keep them topped up if we don’t run the engines for a while. The wiring turned out a lot easier to run than I planned, so that was a nice surprise. We mounted the units inside cabinets and kept the AC plugs coiled up and ready to plug in to a nearby outlet.

We’ve had the system up and operational for a little bit now and I think it’s going to work out just fine for us! We’re still waiting on the solar panels for the rear arch, and once we get those in place we’ll be fully energy independent! 🙂