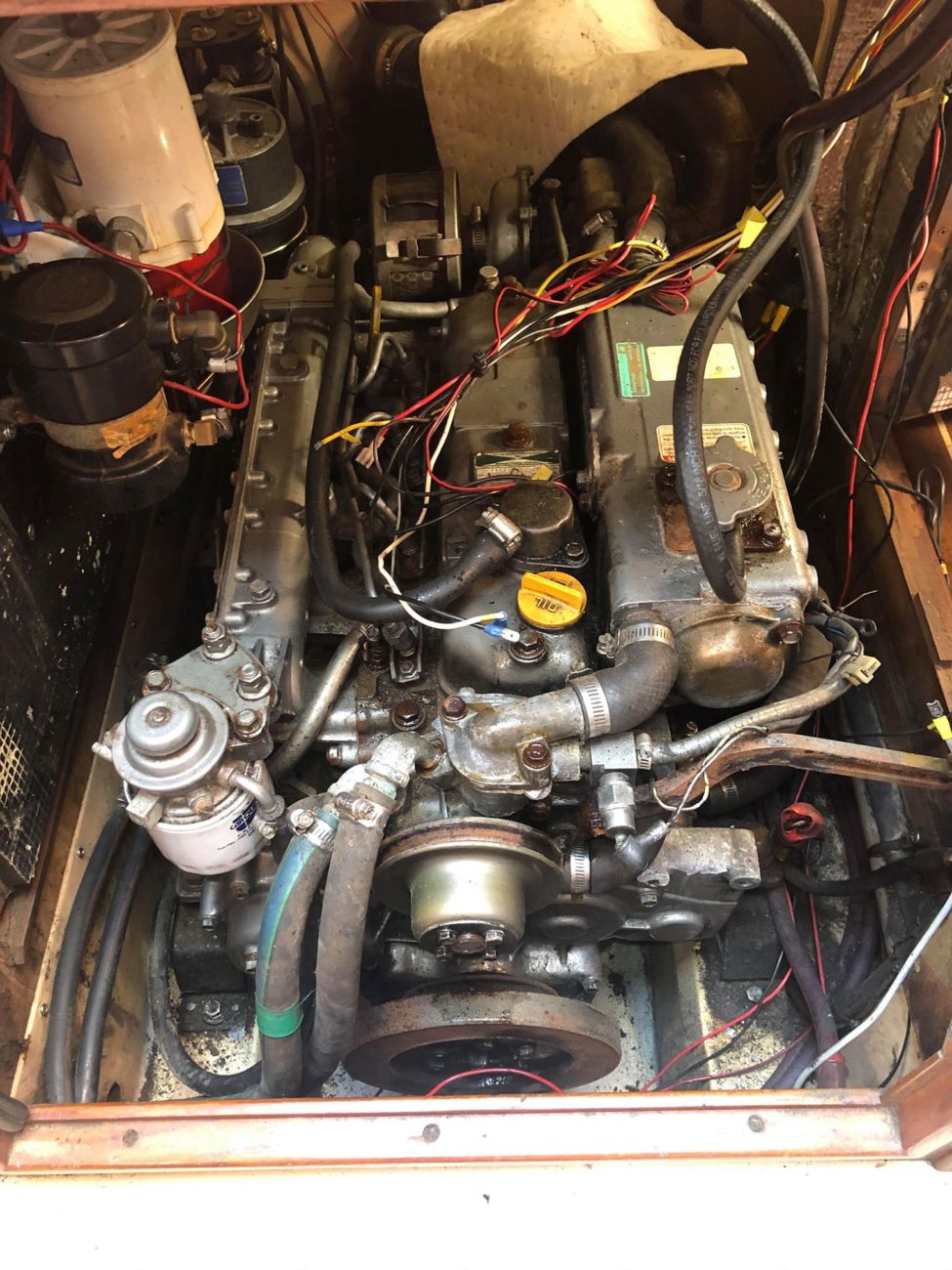

Today started with Jason wanting to take off the rotted exhaust hose from the engine so I could clean and paint the aft lazarette. Shouldn’t have been a big deal at all however once he got the hose off we realized that the turbo outlet had water in it… and it obviously should not. So that’s not good… After a lengthy chat with Caroline’s dad the diesel mechanic, who seems amused by my antics, we decided that the turbo probably needs to be rebuilt. I set to work removing it. The most irritating part is that literally every single fluid started leaking out of the turbo and engine and nothing I did would catch it! I had drain tubs and oil absorbing cloths… and nothing really worked so I ended up just spilling coolant, diesel, and oil pretty much everywhere. I actually love the smell of diesel, but coolant is literally the worst… it’s sticky and gross and I hate it and now it’s all over my hands and my tools. Meh! After minimal fighting, I finally got the turbo removed from the engine along with the intake pipe and various other odds and ends…

As usual, in order to get to one thing on the boat, you need to remove 5 other things. That was the case here as well. The previous owner had added a flow alarm and secondary strainer on the raw water side of the engine after the raw water pump. This is unusual since usually the only strainer is located after the hull opening and the raw water pump connects directly to the engine. What the PO was trying to do was add the strainer to catch and bits of the rubber impeller blades that might break off of the raw water pump before it enters the engine and clogs the heat exchanger. This is sound in theory, however I didn’t like having another strainer to maintain, and didn’t like the additional piping introduced into a system that wasn’t designed for it!

The boat also has a custom fabricated exhaust elbow. It’s pretty nice looking, but I’m hoping it was designed correctly. The previous owner had good intentions, but they seem to always be slightly misplaced. I’m assuming a professional made this.

I’ve also still been working on removing the fuel lines from the old generator and have decided to just put the engine back to the factory configuration. I can always change things around later if I want, but since I’m not sure what’s been done and I want the motor to be reliable, I don’t want all kinds of hacked together fuel hose. The boat has a plywood panel added in the back by the transmission that housed the big fuel filter for the generator, an extra fuel pump, and some sort of obsolete specialty fuel filter that made up a fuel polishing system. While I would very much like to have a fuel polishing system on the boat, I want it to be on its own dedicated fuel lines and not teed into the main engine fueling. The PO also did some “special” wiring to the fuel pumps, but cut and zip tied the original fuel pump wiring inside the engine compartment. I haaaate open ended wires, so that is definitely getting fixed!

So like all true boat projects, we started with one and ended up with no less than 4… it is what it is!

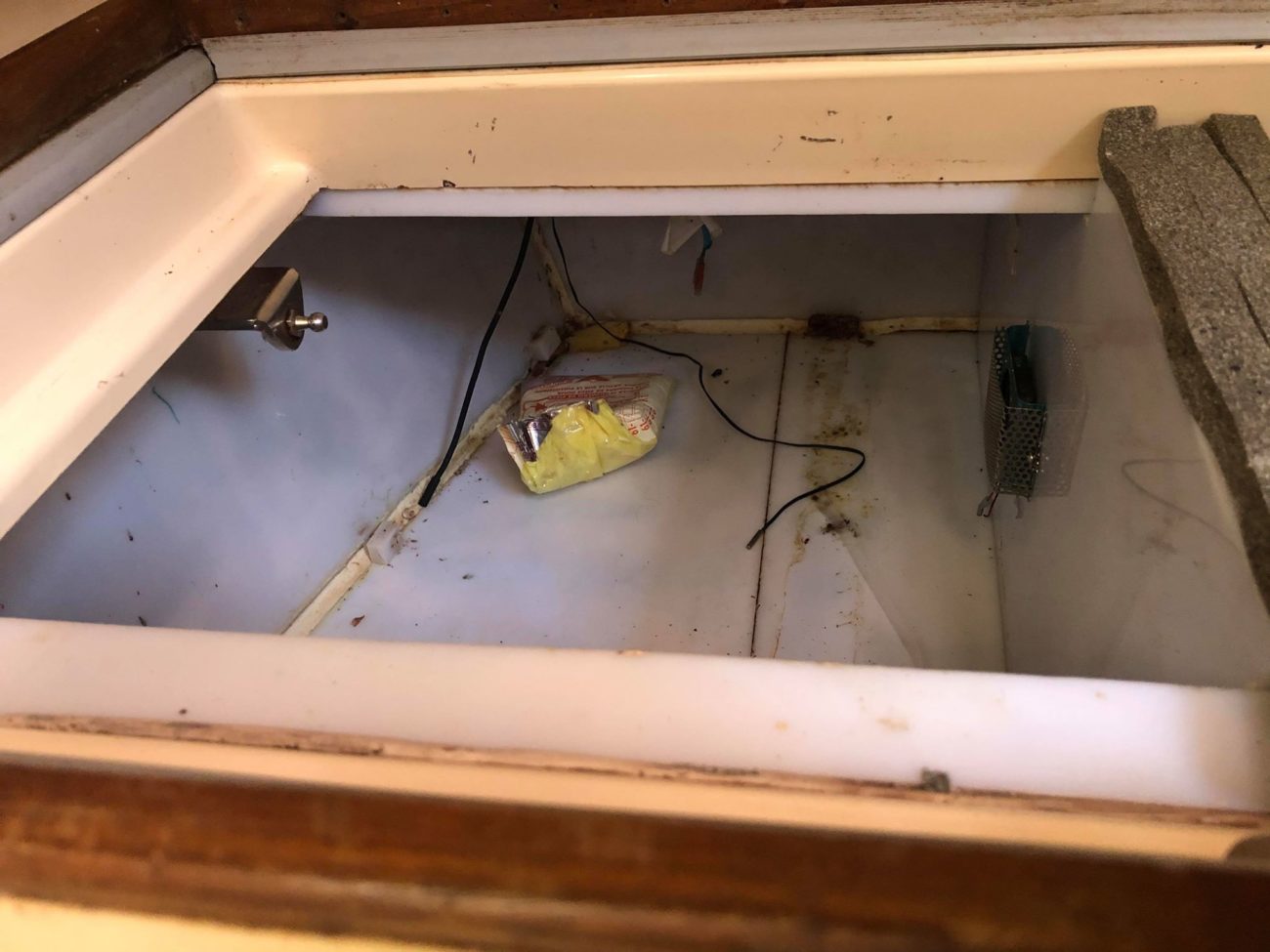

While I was toiling with the engine (words were said.. use your imagination…) Jason started the removal of the refrigeration system. We have 2 shiny new air cooled ones in boxes in our living room!

As usual, lots of removals! Maybe someday we will get to start putting things back together on the ole girl!