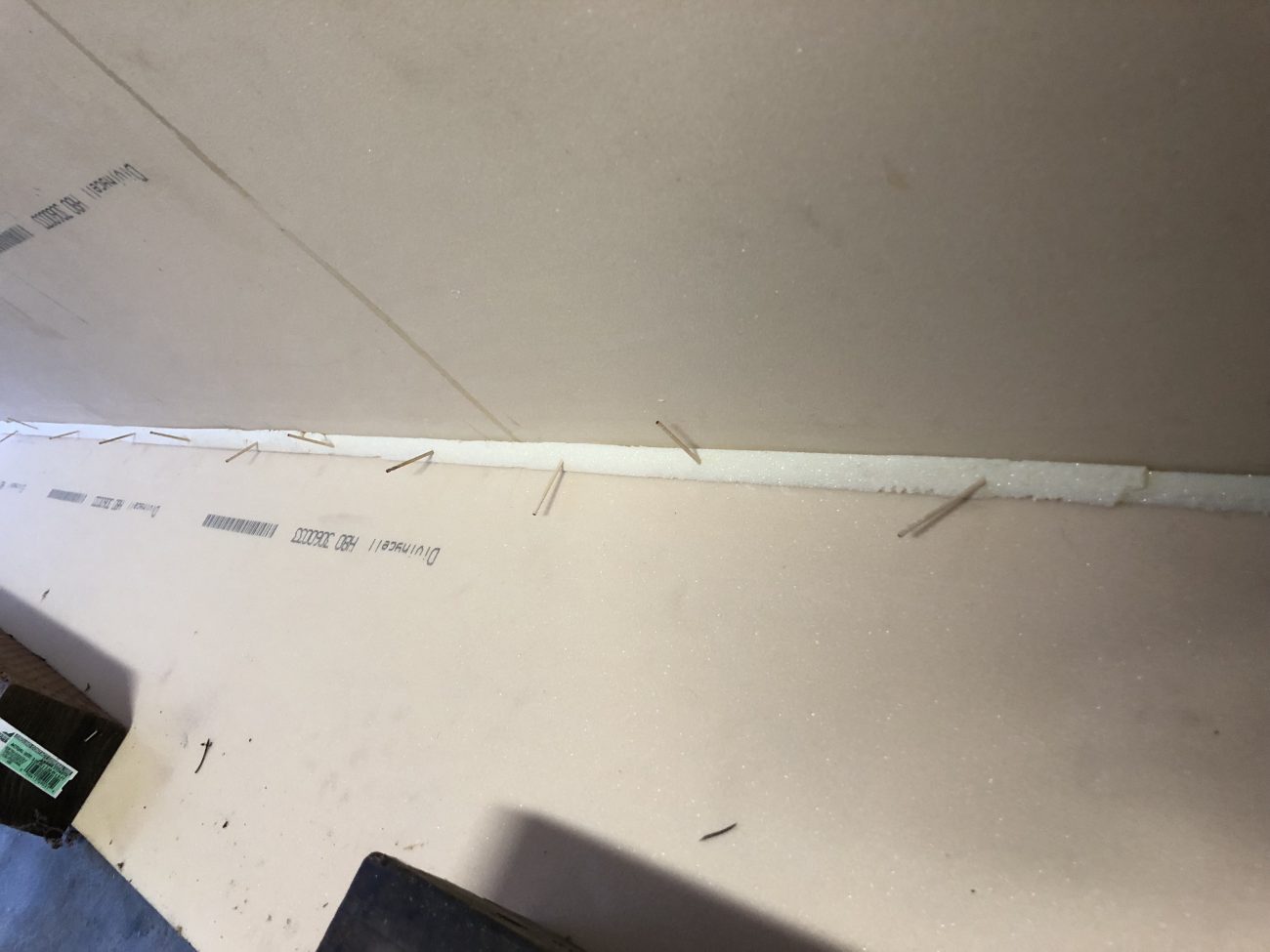

So we’re ready to get started on the build with our fancy structural foam and our roll of fiberglass! The lady at RevChem gave us two suggestions: lay up one side of each panel flat first before assembly, and to keep panels together, use toothpicks! Noted, fiberglass goddess!

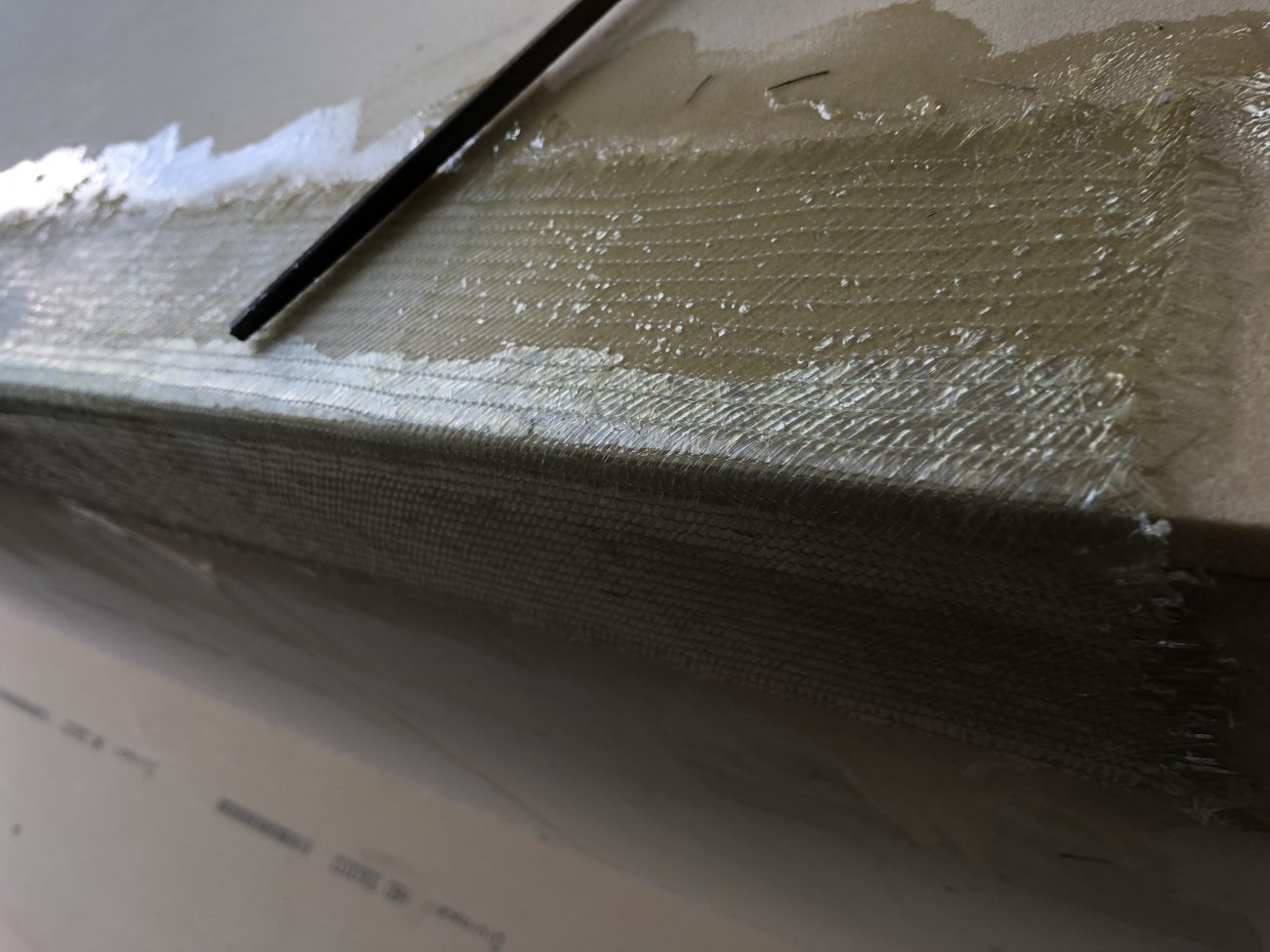

So now we almost have a full tub piece built! time to start glassing the corners! however, we did make a little mistake… we didn’t round off the corners at all, just hoped the fiberglass would mold around them… it didn’t. This left us with a huge bubble along the edge of two sides. At this point we realized that all outside edges needed to be sanded to a radius. But what to do with inside edges? We ended up cutting little corner pieces out of a scrap of foam and gluing them in place. Apparently the original Gorilla Glue foams when it sets up and is perfect for foam because it fills all the little voids and is easy to sand.

We’ve learned a lot already! There are limits to what fiberglass will bend to, keeping things square is hard with none of your flat surfaces are actually flat, Divinycell foam is super easy to work with, and you’re going to need way more resin than you think…

We’re now actually ready to start glassing things in and finish up the tub portion of our sweet new camper!