After spending weeks hashing out our final design and modeling it in 3d, we know we want a cabover with a pop top for space and as low profile as possible elsewhere. Now it comes down to the materials… Which is a big decision. Since we’re trying to lower weight, we’re looking at the more exotic materials like honeycomb core, end grain balsa wood, and structural foam. They cheapest of these come in at over $60 for a single sheet. There’s a surprising lack of information on what to use to build a camper. (believe me, I googled my ass off!) You have the boat builder guys who use 10 layers of fiberglass and don’t trust any material not made in the 1960’s. Then you have the teardrop trailer guys who will laminate damn near anything with resin and hope for the best. Seriously, one guy was using regular household cloth instead of fiberglass. People have been building truck campers and trailers out of regular plywood for a long time, but they’re super heavy which is exactly what we didn’t want. I also haaaaate sawdust for some unknown reason. (literally, it’s the worst…)

I’m sure you can imagine what happens when you have two engineers on the same project with no adult supervision… Every stress and method of loading was discussed. The various strengths and material properties of every core material was charted in a large excel spreadsheet. At the end of the day, we found a fairly local provider of composites and coring materials, they showed us what they had and recommended Divinycell H-80 structural foam. It’s lightweight, has good strength properties, is waterproof (won’t rot like balsa would!). The only downside was the price, but since we were buying so many sheets, they even cut us a deal. We decided to go big or go home and go ahead and purchase an entire roll of fiberglass and 10 gallons of resin. 😮

We had looked at Divinycell foam a bit, but had crossed it off the list due to cost. It’s awesome that we were able to find some at a good value! Our top contender was Nidacore, a plastic honeycomb material, but according to the lady at RevChem, it soaks up resin really bad and would end up being heavier. Overall, it doesn’t really matter at this point. We’ve made a decision and it’s game on!

That pretty much sums up the way Jason and I make decisions. We agonize for months at a time and then just go “eh, what the hell!”

Here is a great article about composite materials and their relative forces if you’re into that sort of thing. Either way, we now have 11 sheets of foam in the back of our truck.

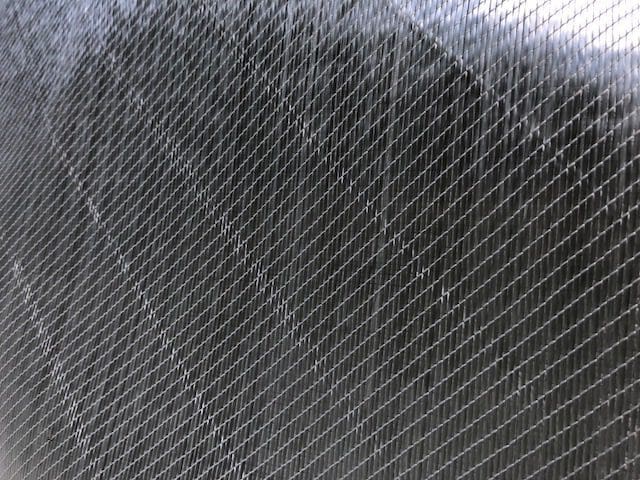

The nice lady at RevChem recommended this 1708 biaxial E-glass two layer fiberglass. It has a thin matting on one side for adhesion, and a stitched weave on the other so it doesn’t fall apart. It’s super thick but since we don’t really have any experience with fiberglass we just took her suggestion and went with it. It’s cheaper by the roll… so we have an entire roll now.

We were planning on using actual epoxy since we have experience with it and actually have some leftover from boat projects, but it was going to be a scale of magnitude more than the polyester resin. We decided to save some money. Time will tell if that’s a good decision or not.

So we have plans and we have materials… Since money has now been invested it’s time to get cracking!